NTP stands for Network Time Protocol,

and it is an Internet protocol used to synchronize the clocks of

computers to a time reference.

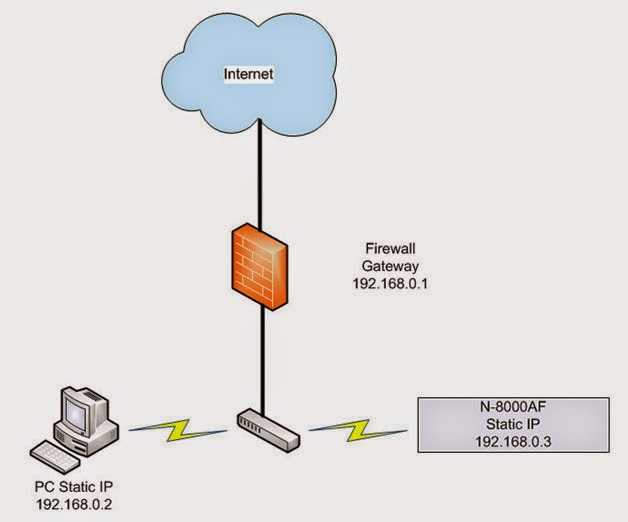

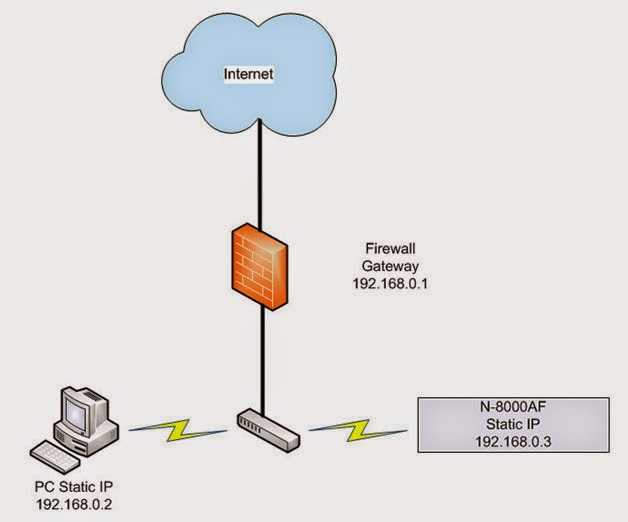

For this to work requires that the N-8000AF can reach the NTP Server on the Internet.

There will different ways of doing this but it is important to note the N-8000 system does require static IP addressing. In this example, a request was made to the IT administrator to provide a range of static IP address that could get through a networks gateway to the Internet.

By using these static IP addresses the computer programming the N-8000 system and the N-8000AF would be able to reach the NTP time server.

In the N-8000 Programming Software, open to the General > System Settings Tab.

Set the N-8000AF as the Clock Master and NTP Client.

In the NPT Settings enter the NTP Server address, server port and sync time in hundred hours.

If you now saved and uploaded your program file, the N-8000AF would be ready to send and receive time adjustment.

How does NTP handle the daylight savings time switchovers?

For this to work requires that the N-8000AF can reach the NTP Server on the Internet.

There will different ways of doing this but it is important to note the N-8000 system does require static IP addressing. In this example, a request was made to the IT administrator to provide a range of static IP address that could get through a networks gateway to the Internet.

By using these static IP addresses the computer programming the N-8000 system and the N-8000AF would be able to reach the NTP time server.

In the N-8000 Programming Software, open to the General > System Settings Tab.

Set the N-8000AF as the Clock Master and NTP Client.

In the NPT Settings enter the NTP Server address, server port and sync time in hundred hours.

If you now saved and uploaded your program file, the N-8000AF would be ready to send and receive time adjustment.

How does NTP handle the daylight savings time switchovers?

The Ability to synchronize to an NTP Time Server is now possible with the latest N-8000 Programming software ver. 4.1.0 and N-8000AF firmware ver. 4.10. This feature will keep a schools bell schedule on time year after year without ever drifting.

Because

NTP is based on UTC which does not have a daylight savings time period,

a switchover is not necessary inside the NTP system. The operation

systems of servers and clients are solely responsible for switching

from/to DST.

You will need to enable DST settings in the N-8000 to keep Bell Schedules on time in the US with only a few exceptions.

You will need to enable DST settings in the N-8000 to keep Bell Schedules on time in the US with only a few exceptions.

Here is are a couple examples of when there was a successful and a not so successful NTP time adjustment.

At 09:45:30 you see the NTP start and then 09:45:30 NTP Complete. Time adjustment was made and system is working as expected. Now see 14:30:34 and you can that there is an NTP error. Let’s explore how to troubleshoot an NTP error.

- Check to see if the NTP server is sending a Time Adjustment back. There a number way to test an NTP server, here is a simple to use web site

- This web site allows you to enter a NTP address and check for a response.

NASA NTP Server

29 Jan 20:50:43 ntpdate[16444]: ntpdate 4.2.6p5@1.2349-o Mon May 20 14:24:36 UTC 2013 (1) server 198.123.30.132, stratum 0, offset 0.000000, delay 0.00000

UCLA NTP Server

29 Jan 20:52:17 ntpdate[16889]: ntpdate 4.2.6p5@1.2349-o Mon May 20 14:24:36 UTC 2013 (1) server 164.67.62.194, stratum 1, offset 0.005516, delay 0.19301

29 an 20:52:32 ntpdate[16889]: adjust time server 164.67.62.194 offset 0.005516 sec

Tech Tip: First test to see if the NTP server is sending back a time adjust. If it is and you are still getting an error proceed with these instructions. Test the NTP Server using the same PC that is programming the N-8000 System. For example if your N-8000AF is set to 10.10.1.10 you should be able to set a PC to that same static IP address and see it get a valid return. Also disconnect the N-8000AF when doing this test so there is not an IP conflict.

- Check the NTP Port

- Make sure the UDP port 123 is open on all firewalls between you and the remote time servers that you wish to synchronize to. For more information please visit this link from ntp.org

- Check the N-800AF firmware version

- On the N-8000AF open the browser page to System Management and verify the firmware version is 4.10 or later.

This link will provide a database of possible NTP servers worldwide.

http://support.ntp.org/bin/view/Servers/WebHome

As of this writing these two servers have been tried with success:

UCLA NTP server in UCLA (164.67.62.194)

NTP Server Port 123

Internet Multifeed (MFEED) –Japan (210.173.160.57)

NTP Server Port 123

NOTE: The NTP Server Port will always be 123 for all NTP servers.