By Jim McGuinness, Product Support Specialist

We get many calls about distributed audio and the connections associated with those systems. Sometimes, the applications are new systems and sometimes they are replacement systems. For new systems it might be a bit easier, since the entire system will be installed fresh and you should have control over most, if not all of the variables. However, in a replacement system, you don’t always have control over some of the makeup of the system, namely- the wiring, in many cases. This could be due to cable access and being able to rerun cable, or simply that replacing wiring is labor intensive and it would push the project beyond the budgetary limits set. Therefore, going with existing wiring is often the decision. You could just have a client that doesn’t want his building knocked apart for wiring if at all possible, as he’s more interested in just replacing the head-end equipment.

Applications for distributed audio installations are all over the place these days. Typical examples are schools, hospitals, nursing homes, hotels, malls, really…you name it. When we look at these applications, we have to look at the length of cable versus the farthest distance in the system, as well as the power/current being pushed through the system. This is a very important consideration on new or replacement systems, but especially replacement systems where cabling will be reused. 70V systems are much more forgiving with respect to cable gauge versus a 25V system. We usually recommend 70V applications where applicable. In some cases, it is not possible based on local code. A couple of examples might be in hospitals or schools. Often they are 25V systems, not 70V systems.

Now there’s one other factor that also has to be considered when replacing an existing system where cabling will be reused. Was the cabling adequate for the system from the get go? Meaning- was the proper gauge of wire used for the wattage load of the system? This should always be checked. What if the wattage of the system changes to a higher value? That’s another wiring consideration. If you are replacing a system that was originally a 25V speaker system with a 70V speaker system, then generally speaking, you should be ok. However, going the other way around is a major concern.

Included in this article is a cable guide chart for both 25V and 70V systems. The yellow highlighted example in the chart shows a 100 watt typical load for both a 25V and 70V system based on keeping about a 225 foot run of cable for both systems. For a small store, this might be a pretty typical scenario. The important point is to look at the wire gauge difference for these two systems. For 70V you can use a relatively light, 18 gauge wire. However, for the same system in 25V, a heavy 12 gauge wire will be needed to get the same job done. Signal loss was also considered when this chart was made, meaning that the resistance of the wire itself has to be considered as part of the added load to the amplifier.

In the second orange circled example, we looked at it a different way. We looked at a 70V system where the impedance and wire gauge will be the constants, and using those constants to find the approximate point on the 25V system chart. Now the distance went up a bit, but the real key here is the resulting power load limit. Only a 15 watt system can be installed using the same gauge of wire. In this example that’s a power factor of about 7 to 1!

So, it’s really important to look at these simple things to get a system to perform properly for years to come and not have any issues with the system performance. Failed systems yield unhappy customers and we all know what that means.

Happy connecting………

TOA Electronics, Inc. is dedicated to the development, manufacturing and distribution of premier audio products. TOA Corporation was founded in Kobe, Japan over 80 years ago. All of TOA’s products bear its name. TOA operates in over 100 countries worldwide, with manufacturing facilities are found in nearly every major market area. TOA’s extensive line of audio products includes amplifiers, speakers, mixers, wireless microphone systems, digital processors and network audio.

Wednesday, August 6, 2014

Product Spotlight: TOA 5000 Series Wireless Microphone Systems

By Bob Tamburri, Marketing & Technical Support Manager

It may surprise you to learn that TOA has been manufacturing wireless microphones since 1964 (that’s way longer than most currently popular wireless mic manufacturers). We’ve even been the technology supplier for other wireless manufacturers. Needless to say, TOA has a lot of experience when it comes to wireless mics. The 5000 Series represents the latest permutation of that experience.

So, what’s so special about the 5000 Series?

First and foremost (and this is where TOAs long experience comes in) is the very robust UHF transmission & reception system employed by the 5000 Series. TOA uses 3-stage filtering to help reduce the impact of interfering signals. These filters create a tighter “window” to allow only the desired signals through, while undesired signals are more effectively locked out.

Second, the TOA mics (both hand-held and body-pack) are designed to be extremely efficient (over 10 hrs of operation with a single AA battery) and are extremely lightweight and ergonomic (not big, heavy paperweights). We even provide an anti-roll guard on the hand-held mic body to prevent them from rolling off a table. The 5000 Series mics are also equipped with charging contacts and are compatible with the optional NiMH batteries and charging system, which eliminates the need to continually replace batteries and assures that your wireless system is always ready to perform.

Lastly, the 5000 Series squeezes lots of performance and features into a cost-competitive package. These include features not often found on similarly-priced systems such as frequency-scanning, antenna daisy-chain ports* and comprehensive LCD displays, as well as the ability to operate up to 16 simultaneous systems. And, to help cope with the ever changing UHF spectrum landscape, the 5000 Series models are available on frequencies from 576mHz to 698mHz, so you’ll always find a place to work that’s free from interference.

TOA offers a range of transmitters from hand-held (WM-5225, WM-5265 & WM-5270) to body-pack (WM-5325 with a choice of microphones) as well as Tuners (WT-5800, WT-5805 & WT-5810, plus the modular WTU-4800/WT-4820 system. Add all the necessary options (remote antennas, mics, distributors, etc…) and you’ve got a complete wireless solution that works for just about any situation. If that’s not enough, TOA protects your investment with a 5 year audio warranty (more than any other wireless manufacturer).

For more information, visit out website by clicking here.

Also, check our handy Wireless System Configuration Guide, which will help you choose the system that suits your needs by clicking here.

*WT-5800 & WT-4820 Only

It may surprise you to learn that TOA has been manufacturing wireless microphones since 1964 (that’s way longer than most currently popular wireless mic manufacturers). We’ve even been the technology supplier for other wireless manufacturers. Needless to say, TOA has a lot of experience when it comes to wireless mics. The 5000 Series represents the latest permutation of that experience.

So, what’s so special about the 5000 Series?

First and foremost (and this is where TOAs long experience comes in) is the very robust UHF transmission & reception system employed by the 5000 Series. TOA uses 3-stage filtering to help reduce the impact of interfering signals. These filters create a tighter “window” to allow only the desired signals through, while undesired signals are more effectively locked out.

Second, the TOA mics (both hand-held and body-pack) are designed to be extremely efficient (over 10 hrs of operation with a single AA battery) and are extremely lightweight and ergonomic (not big, heavy paperweights). We even provide an anti-roll guard on the hand-held mic body to prevent them from rolling off a table. The 5000 Series mics are also equipped with charging contacts and are compatible with the optional NiMH batteries and charging system, which eliminates the need to continually replace batteries and assures that your wireless system is always ready to perform.

Lastly, the 5000 Series squeezes lots of performance and features into a cost-competitive package. These include features not often found on similarly-priced systems such as frequency-scanning, antenna daisy-chain ports* and comprehensive LCD displays, as well as the ability to operate up to 16 simultaneous systems. And, to help cope with the ever changing UHF spectrum landscape, the 5000 Series models are available on frequencies from 576mHz to 698mHz, so you’ll always find a place to work that’s free from interference.

TOA offers a range of transmitters from hand-held (WM-5225, WM-5265 & WM-5270) to body-pack (WM-5325 with a choice of microphones) as well as Tuners (WT-5800, WT-5805 & WT-5810, plus the modular WTU-4800/WT-4820 system. Add all the necessary options (remote antennas, mics, distributors, etc…) and you’ve got a complete wireless solution that works for just about any situation. If that’s not enough, TOA protects your investment with a 5 year audio warranty (more than any other wireless manufacturer).

For more information, visit out website by clicking here.

Also, check our handy Wireless System Configuration Guide, which will help you choose the system that suits your needs by clicking here.

*WT-5800 & WT-4820 Only

Wednesday, June 4, 2014

9000M2 Preset EQs for TOA Speakers

By Jim McGuinness, Product Support Specialist

In continuing to make installation faster and better for the installer, TOA has included built-in output channel speaker EQ settings in the software that’s available for this mixer amplifier and we wanted to remind our installers of this added benefit. There are 30+ speaker EQs to choose from for many popular models of our TOA speakers. These EQs will make your project sound better and sound more uniform, yielding a better installation result. This should make a happier customer and generate a better potential for a repeat customer or even new business due to positive word of mouth, or should we bring ourselves more up to date like word of Twitter, Facebook, Instagram, etc. Dare I say e-mail?

So old school!

Implementing EQ settings is very easy. First open your software project so that you get the main screen as shown below. Then click on the Blue EQ button of the channel you want to equalize. The EQ page will display at the bottom of the screen.

Remember for EQ settings, you will have to click on the EQ button for each channel you want to equalize. This is different from the other output settings which will display all channels at the bottom of the screen. This I primarily due to EQ information takes up too much space to be able to display all EQ channels at the same time.

Next, click on the dropdown menu option that by default says “ALL FLAT.”

You will see the list of speaker options to choose from as shown below.

Once you click on the speaker option needed, the EQ curve(s) will be available for review on the lower part of the screen. The HX-5 speaker is listed in this example. If you would like to review the EQ frequency points, click on the dropdown for the Select (1-12). There you will have up to twelve points that can be reviewed if available. Some speakers may only have 1 or 2 points where other speakers might have 7 or 8 points. In the case of the HX-5, there are 5 points that you can review. As you review EQ points, when the next point number to be reviewed lists “Through,” then there are no more points for that speaker.

Now for an additional programming trick. If you have multiple channels with the same speaker, you can copy paste from one channel to another. Here are the simple steps for this.

First set the EQ curve desired on the lower part of the screen as previously described above on a channel to be equalized. In this example Channel 1 was chosen. Once selected, right button click

your mouse on the CH1 box

on the top part of your screen and select Copy.

on the top part of your screen and select Copy.

Then right button click on the target channel box you want to copy the EQ curve to and click paste. In this example channel 2

was chosen. That’s it. You will be able to confirm the curve on the bottom of the screen.

Now some final notes regarding Preset EQs.

Preset EQs can only be initially set from the programming software, not by the front panel controls of the mixer amplifier. Once set and loaded to the mixer amplifier, Preset EQs can be turned on and off via the front panel.

Preset EQs can only be reviewed, not changed. If you need to change a point in a Preset EQ for your installation application, you will need to review the EQ points as described above and write down the parameters for each point. Then you can modify the EQ curve as necessary by creating your own EQ curve from the software or the front panel controls.

Importantly remember to save your scene for the EQ settings you have made. Don’t for get to save the project to your computer as well for backup. Lastly click on Communication and select Upload PC to 9000 > All Data, to get your changes in the amplifier mixer.

Happy sound shaping……

In continuing to make installation faster and better for the installer, TOA has included built-in output channel speaker EQ settings in the software that’s available for this mixer amplifier and we wanted to remind our installers of this added benefit. There are 30+ speaker EQs to choose from for many popular models of our TOA speakers. These EQs will make your project sound better and sound more uniform, yielding a better installation result. This should make a happier customer and generate a better potential for a repeat customer or even new business due to positive word of mouth, or should we bring ourselves more up to date like word of Twitter, Facebook, Instagram, etc. Dare I say e-mail?

So old school!

Implementing EQ settings is very easy. First open your software project so that you get the main screen as shown below. Then click on the Blue EQ button of the channel you want to equalize. The EQ page will display at the bottom of the screen.

Remember for EQ settings, you will have to click on the EQ button for each channel you want to equalize. This is different from the other output settings which will display all channels at the bottom of the screen. This I primarily due to EQ information takes up too much space to be able to display all EQ channels at the same time.

Next, click on the dropdown menu option that by default says “ALL FLAT.”

You will see the list of speaker options to choose from as shown below.

Once you click on the speaker option needed, the EQ curve(s) will be available for review on the lower part of the screen. The HX-5 speaker is listed in this example. If you would like to review the EQ frequency points, click on the dropdown for the Select (1-12). There you will have up to twelve points that can be reviewed if available. Some speakers may only have 1 or 2 points where other speakers might have 7 or 8 points. In the case of the HX-5, there are 5 points that you can review. As you review EQ points, when the next point number to be reviewed lists “Through,” then there are no more points for that speaker.

Now for an additional programming trick. If you have multiple channels with the same speaker, you can copy paste from one channel to another. Here are the simple steps for this.

First set the EQ curve desired on the lower part of the screen as previously described above on a channel to be equalized. In this example Channel 1 was chosen. Once selected, right button click

your mouse on the CH1 box

on the top part of your screen and select Copy.

on the top part of your screen and select Copy.Then right button click on the target channel box you want to copy the EQ curve to and click paste. In this example channel 2

was chosen. That’s it. You will be able to confirm the curve on the bottom of the screen.

Now some final notes regarding Preset EQs.

Preset EQs can only be initially set from the programming software, not by the front panel controls of the mixer amplifier. Once set and loaded to the mixer amplifier, Preset EQs can be turned on and off via the front panel.

Preset EQs can only be reviewed, not changed. If you need to change a point in a Preset EQ for your installation application, you will need to review the EQ points as described above and write down the parameters for each point. Then you can modify the EQ curve as necessary by creating your own EQ curve from the software or the front panel controls.

Importantly remember to save your scene for the EQ settings you have made. Don’t for get to save the project to your computer as well for backup. Lastly click on Communication and select Upload PC to 9000 > All Data, to get your changes in the amplifier mixer.

Happy sound shaping……

Wednesday, April 2, 2014

ZM-901x Remote Buttons as Volume Controls

By James McGuinness, Product Support Specialist

We get lots of questions regarding the various uses for the serial RS-485 ZM-9011, ZM-9012, ZM-9013 and ZM-9014 remotes. One popular one is about volume control. Now the ZM-9012 (rotary volume only) and the ZM-9014 have a dedicated rotary volume control and it can be assigned to be an input channel volume control, an output channel volume control, a grouped input channel volume control or a grouped output channel volume control. But did you know that you can make the buttons on so equipped serial remotes into volume controls similar to the functionality of a ZM-9001 or ZM-9002 wired remote control? The only requirement is that you have available pairs of contact inputs and outputs available for this application.

So for this example let’s use an A-9060SM2 where we are going to have two inputs with button volume controls and a master output volume control using a ZM-9014 serial remote control. Of course to complete the basic equipment list you will need an input module such as the D-001T, an RC-001T serial remote control module, and its power supply the AD-246.

For connections we will not go over the basic input and output connections, and the basic RC-001T connections which you should know by now. Of course if you need a reminder, examples are available in the instruction manual. However, let’s look at the connections required for this application as they apply to the 14 pin control connector.

Standard Control Port Available On All 9000M2 Mixers Shown Above

We are going to marry two sub-systems together, the RS-485 serial remotes along with our contact closure circuits. To start to make this application work, we need to connect 4 input contact closures to 4 output contact closures. The reason for this is we can control the output contact closures with the serial remotes and operate them via the buttons on the remote, and we can set the input contact closures for volume control use. Can you see where we’re going with this?

In the picture below you will see the physical connections necessary to make this work. It’s simple, connect input 1 to output 1 and so on. A ground or “E” connection is not necessary as we are not connecting off the mixer itself, so internal ground will take care of it.

Now you have all the connections necessary to make this work, so let’s take a look at the programming screens to finish the control.

First we want to go to Setting and then C-IN Setting…

On the next page you will see the options available for the C-IN control. In our example we choose volume up and down twice as shown under Parameter and the input sources are married to a pair of volume up and down contacts using the Channel/Scene dropdowns. You then can choose the resolution of the button presses between 0.5dB ~ 10dB in their respective dropdowns. We have chosen 1dB in this example.

Once this is all done click OK and the screen will save and close. Now we will move on to the serial remote settings.

First go to Setting and then Remote Setting Wizard…

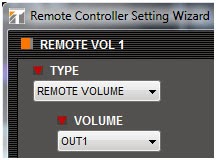

On the next screen you will see the remote settings page for 2-wire remote controls which are the

ZM-9001 & ZM-9002 which we are not using. Select None for both Remote Volume 1 & 2 and click Next.

Then we will get the serial remote start page.

On the initial serial remote setup page above, select 1 remote, Simultaneous Mode, and the ZM-9014 remote options. The ZM-9014 comes set from the factory at address 0 so you won’t need to change this typically. However, please check that the software setting for address matches the remote’s setting. Normally you will start at address 0. Now the reason why we chose Simultaneous Mode for this exercise is let’s say this is for a conference area. The mic may need to be on at the same time as the BGM music or audio source. This setting will allow that. If set to Exclusive mode, you will only be able to choose one input at a time and pressing the volume keys may in some cases affect your input source. Okay, now click Next.

Now you see the programming screen of the ZM-9014 above. From the Function Select dropdown menus you will select Change C-OUT for all 4 buttons. Under Assigned Value you have 2 options, Level and Toggle. This is somewhat confusing. I would rather have the terms Pulse for Level and Latch for Toggle. So for our application we want to choose Level “Pulse” for all four dropdowns. To the right of this option you have dropdowns which are unlabeled. These dropdowns are the contact control output settings. Set the options as shown 1 ~ 4 as we have used buttons 1 ~ 4 in order and that’s how we wired the contact inputs and outputs earlier in our discussion. Lastly for the rotary volume control, select Output Volume and the Assigned output channel 01. Then click Finish.

Now you’re all set. Your ZM-9014 will work completely like a volume control. The upper two buttons will be the volume control for the Mic and the bottom two buttons will be the volume control for the BGM or audio input. The rotary volume control will be the master output volume control.

TIP: Now if you want to have more than one of these remotes in the room, no problem. You can add more ZM-9014 volume controls around the room, just program them similarly as the first remote. You will just have different address settings for each on the initial serial remote settings page. The neat thing is that each volume control knows what the other one is doing so the volume display on each volume control will be the same around the room. No wondering what one volume control is doing versus another one.

Happy programming………remotely speaking.

We get lots of questions regarding the various uses for the serial RS-485 ZM-9011, ZM-9012, ZM-9013 and ZM-9014 remotes. One popular one is about volume control. Now the ZM-9012 (rotary volume only) and the ZM-9014 have a dedicated rotary volume control and it can be assigned to be an input channel volume control, an output channel volume control, a grouped input channel volume control or a grouped output channel volume control. But did you know that you can make the buttons on so equipped serial remotes into volume controls similar to the functionality of a ZM-9001 or ZM-9002 wired remote control? The only requirement is that you have available pairs of contact inputs and outputs available for this application.

So for this example let’s use an A-9060SM2 where we are going to have two inputs with button volume controls and a master output volume control using a ZM-9014 serial remote control. Of course to complete the basic equipment list you will need an input module such as the D-001T, an RC-001T serial remote control module, and its power supply the AD-246.

For connections we will not go over the basic input and output connections, and the basic RC-001T connections which you should know by now. Of course if you need a reminder, examples are available in the instruction manual. However, let’s look at the connections required for this application as they apply to the 14 pin control connector.

Standard Control Port Available On All 9000M2 Mixers Shown Above

We are going to marry two sub-systems together, the RS-485 serial remotes along with our contact closure circuits. To start to make this application work, we need to connect 4 input contact closures to 4 output contact closures. The reason for this is we can control the output contact closures with the serial remotes and operate them via the buttons on the remote, and we can set the input contact closures for volume control use. Can you see where we’re going with this?

In the picture below you will see the physical connections necessary to make this work. It’s simple, connect input 1 to output 1 and so on. A ground or “E” connection is not necessary as we are not connecting off the mixer itself, so internal ground will take care of it.

Now you have all the connections necessary to make this work, so let’s take a look at the programming screens to finish the control.

First we want to go to Setting and then C-IN Setting…

On the next page you will see the options available for the C-IN control. In our example we choose volume up and down twice as shown under Parameter and the input sources are married to a pair of volume up and down contacts using the Channel/Scene dropdowns. You then can choose the resolution of the button presses between 0.5dB ~ 10dB in their respective dropdowns. We have chosen 1dB in this example.

Once this is all done click OK and the screen will save and close. Now we will move on to the serial remote settings.

First go to Setting and then Remote Setting Wizard…

On the next screen you will see the remote settings page for 2-wire remote controls which are the

ZM-9001 & ZM-9002 which we are not using. Select None for both Remote Volume 1 & 2 and click Next.

Then we will get the serial remote start page.

On the initial serial remote setup page above, select 1 remote, Simultaneous Mode, and the ZM-9014 remote options. The ZM-9014 comes set from the factory at address 0 so you won’t need to change this typically. However, please check that the software setting for address matches the remote’s setting. Normally you will start at address 0. Now the reason why we chose Simultaneous Mode for this exercise is let’s say this is for a conference area. The mic may need to be on at the same time as the BGM music or audio source. This setting will allow that. If set to Exclusive mode, you will only be able to choose one input at a time and pressing the volume keys may in some cases affect your input source. Okay, now click Next.

Now you see the programming screen of the ZM-9014 above. From the Function Select dropdown menus you will select Change C-OUT for all 4 buttons. Under Assigned Value you have 2 options, Level and Toggle. This is somewhat confusing. I would rather have the terms Pulse for Level and Latch for Toggle. So for our application we want to choose Level “Pulse” for all four dropdowns. To the right of this option you have dropdowns which are unlabeled. These dropdowns are the contact control output settings. Set the options as shown 1 ~ 4 as we have used buttons 1 ~ 4 in order and that’s how we wired the contact inputs and outputs earlier in our discussion. Lastly for the rotary volume control, select Output Volume and the Assigned output channel 01. Then click Finish.

Now you’re all set. Your ZM-9014 will work completely like a volume control. The upper two buttons will be the volume control for the Mic and the bottom two buttons will be the volume control for the BGM or audio input. The rotary volume control will be the master output volume control.

TIP: Now if you want to have more than one of these remotes in the room, no problem. You can add more ZM-9014 volume controls around the room, just program them similarly as the first remote. You will just have different address settings for each on the initial serial remote settings page. The neat thing is that each volume control knows what the other one is doing so the volume display on each volume control will be the same around the room. No wondering what one volume control is doing versus another one.

Happy programming………remotely speaking.

Tuesday, April 1, 2014

Installation Spotlight: Madame Tussauds

If you want to meet a celebrity without all of the paparazzi hype, visit Madame Tussauds. With locations in Europe, Asia, Australia, and the United States, Madame Tussauds aims to create distinctive, unforgettable and gratifying guest encounters, realized through the passion of wax. But what would the experience be without great quality sound? Enter David Prentice of Dale Pro Audio in New York who worked hand-in-hand with Kevin Wilkin of TOA Electronics, Inc. to expedite delivery of products which were ordered, literally, at the last minute.

This project was unusual for a number of reasons. Daryl Bornstein of Daryl Bornstein Audio, and his longtime colleague, Roger Jay of Play Sound, were charged with designing and installing a playback system in a pre-existing and relatively small (40' diameter), round, domed room. A truss system, meant to emulate the last U2 tour giant crab stage was installed, from which the speakers would be mounted. The client requested speakers that would look like a concert sound system, but the scale of the room and the limited budget precluded most of the obvious choices.

Initially, they did not consider the TOA HX-5 Variable Dispersion Speaker, which was perhaps the most obvious choice for this type of project considering the look, weight, and cost of the speakers, but because they did not think they would deliver the sound quality or sound pressure level required. They looked at solutions using speakers mounted on the perimeter of the room/truss system, pointing towards the center of the room. This would have been a perfectly acceptable "generic" choice, using small column speakers like the TOA SR-Series Slim Line Array, with additional sub woofers, however they would not address the client's request for the speakers to be an integral scenic element.

More importantly, mounting column speakers on the truss supports would obscure some of the lighting effects in the vertical truss along the wall. It also would have placed the speakers too close to the patrons due to limited height of the truss and the relatively small size of the room, even though the SR-S’s work well fairly close. In short, the column speakers would be intrusive rather than adding to the theatricality of the exhibit. But they did not give up on this solution until fairly late in the design process.

Ultimately, at Roger's urging, they revisited the TOA HX-5 Variable Dispersion Speaker. The client had designed prop line arrays to hang from the center truss. They convinced the client to allow them to substitute the HX-5’s for the props. The HX-5’s fit the scale of the room better than the props, saved the client money because they no longer needed to build the props, and mounting the speakers in the center or the room, facing out towards the curved wall, providing better overall coverage without over exciting the room. Also, the HX-5s came in black, their desired color, unlike the SR-S’s which come in white only. They were thrilled not to have to paint the main speaker system components.

The tight and adjustable vertical pattern of the HX-5 Line Array Speaker, most often used to throw longer distances, was quite effective in keeping sound focused on the guests and off of the walls, even though they were throwing only twenty feet. The wide horizontal pattern allowed for seamless coverage throughout the room. They would not have achieved the same coverage if the speakers had been mounted on the walls facing into the room or if they used conventional, horn loaded (typical trapezoidal) PA speakers. Additionally, having the speakers mounted in the center facilitated having the guests walk into the room and walk directly into the sound from the speakers, creating the effect of walking into a concert in an arena. This is the effect the client had hoped to achieve.

They convinced the client to use more speakers than they had originally considered so that they could achieve better coverage and provide a stereo image throughout the room by feeding alternate speakers with left or right signal content. This was possible because the TOA solution was extremely cost-effective. They used six arrays consisting of one (1) HX-5 Variable Dispersion Speaker and one (1) FB-120 subwoofer flown. They insisted on six (6) subs, rather than two (per the client’s request), because they wanted to have even low end throughout the room. The look and integrated sound of this type of array speaker and sub combination was perfect for this application, and alleviated concerns that they would not get enough extended low end out of just two 12" flown subwoofers flown separately. Using lightweight subs that fly as an integrated part of the system solved a number of problems.

System processing was achieved with a Symetrix Solous 8 and the speakers were powered by three Electrovoice CPS2 series amplifiers. Because of the structure of the center truss supports, the ideal solution would have been eight (8) arrays, rather than six (6), but that was not within their budget, nor would the client agree to that many speakers, when they already thought six were excessive. In the end, the client was thrilled with the look and the sound.

The TOA rigging frames made the job very easy. Combined with the light weight of the array speakers, the installation was far easier than expected. Their biggest challenge, because of how they chose to fly the speakers on the truss, was securing the chain so that it would not move. Ultimately, Jay came up with the solution of using simple hose clamps which worked brilliantly.Bornstein was concerned that the speakers would not sound as good as they needed, or sound like the type of “dance club sound system” that the client had requested for the Music Room, which houses figures of current pop stars.

After entering crossover and EQ data provide by TOA, and then spending time squeezing every ounce of performance quality out of the arrays through additional EQ, dynamics, and balancing hi/mids to lows, they achieved far better results than they could have hoped for. In fact, they were, and remain; astonished that the speakers sound as good as they do, especially in light of Bornstein’s initial listening when the product was first introduced. For a speaker designed to reproduce spoken word in churches, it does a very fine job reproducing loud pop music.

They were charged with providing a robust system that met stringent visual criteria, was within a very tight budget, could be installed within an ambitious (tight) schedule, sounded great both at low and extremely loud volumes, and would function year in and out without failure or maintenance. The HX-5 and FB-120 combination addressed the client's needs perfectly.

Bornstein was also asked to provide a playback system for a stadium crowd sound effect loop in the foyer leading into the Music Room. This space was extremely challenging because it was an odd shape, with a very low ceiling, scenic elements on the walls, and had a very small budget. Again, by choosing a TOA product, the small H-1 Interior Design Speaker, they were able to deliver high quality, focused sound, yet, without an obvious point source, which could be mounted in the ceiling, addressing both the client's aesthetic and budgetary requirements.

After painting the speakers black, they "disappeared" into the ceiling, adding to the overall immerse effect of walking through a pedestrian tunnel into a concert arena. This is saying a lot since the ceiling is only seven feet high! This was a truly inspired solution which Jay came up with. The playback and power for the speakers was provided by a Gilderfluke SD-25 combination digital playback system/amplifier. Once again, the client wanted only two (2) speakers but we felt four (4) were necessary to achieve an immense stereo crowd effect. And this was, indeed, the case. We were able to deliver the four (4) TOA H-1's for less than two of another product we had considered initially. The H-1s were a far better solution.

TOA was chosen over other products because of price, look, ease of installation, and appropriateness of the products. Everything was delivered in time, and the installation was easy due to TOA's clever and efficient rigging and mounting hardware. Bornstein and Jay exceeded the client's expectations with TOA’s solutions.

Friday, February 7, 2014

Multiple Remote Instances on a Budget

By Jim McGuinness, Product Support Specialist

We are always looking for ways to maximize the design for our customers to yield the biggest bang for the buck. Sometimes customers would like more than one remote. If your customer is looking for the same functionality, just multiple locations of the same remote and its functions, we have a little trick you can use. The only requirement is that the ZM-9001 remote is the remote of choice for your project where a scene, page, or volume up and down are the functions to be used.

Now we can’t change the programming requirement for the mixer which is a maximum of two 2-wire remote controls being used on a 9000M2 series mixer, and this will not work if the ZM-9002 remote is required for the project. However, we can wire in multiple ZM-9001s on a single remote port.

Now the programming technique will not change for this multiple remote trick. You would program the remote control the way you always would. The screenshots are shown below.

First click on Setting to get the drop down menu.

Then click on Remote Setting Wizard

You will then get a display for the remote settings.

Select ZM-9001 for Remote Volume 1

You will then get the options you can set for the remote. Displayed are the popular settings.

If Page is selected as shown for the ZM-IN2 button below, you will get a drop down menu to select

the contact closure input to use on the back panel of the mixer’s chassis and as a trigger for the Page

Event programming.

As you can see, any of the scenes can be chosen, and any input or output can be selected to

be controlled when Volume is selected as a function. Additionally, the resolution of the volume change can be set as well.

So what’s left? Just wire as many ZM-9001 remotes to the remote port that has been programmed in standard parallel fashion. Just be sure to connect them all the same way. DO NOT mix the “E” and “Out” connections. You can also daisy chain one remote to the next, if home run wiring is not being done. That’s it!

Now you may have noticed you have a Remote Volume 2 shown above. This is for your 2nd

2-wire remote port. You can do the same thing with this remote option as well. Double bang for the buck! This option, if your project can make use of it, will save you a few hundred dollars minimum over using the serial remotes. Now the 2-wire remotes and serial remotes each have their own advantages, but this is a simple cost saving control option where applicable.

Some last thoughts.

This could give you volume up and down for 6 inputs, 6 outputs, or combination of 6 input and output channels in a standard 2-gang electrical box with multiple instances. You also could use our trick on one port and use a ZM-9002 on the second port. With this combination, you could as an example, program the ZM-9001 port for volume change for 3 input channels and program the ZM-9002 port so the rotary volume control is used as an output volume control and then program the four buttons for scene change. This would be a great solution when using an A-9060SM2, A-9120SM2 or A-9240SHM2 where the requirements of the project match the maximum number of channels, pages and volume settings to be controlled by ZM-9001 and ZM-9002 remotes. An example of this might be a restaurant where the single ZM-9002 would be located at the bar for scene and output volume control and multiple instance input volume controls would be located around the eating area for up to three sources.

Happy installing!

We are always looking for ways to maximize the design for our customers to yield the biggest bang for the buck. Sometimes customers would like more than one remote. If your customer is looking for the same functionality, just multiple locations of the same remote and its functions, we have a little trick you can use. The only requirement is that the ZM-9001 remote is the remote of choice for your project where a scene, page, or volume up and down are the functions to be used.

ZM-9001 Remote

Now we can’t change the programming requirement for the mixer which is a maximum of two 2-wire remote controls being used on a 9000M2 series mixer, and this will not work if the ZM-9002 remote is required for the project. However, we can wire in multiple ZM-9001s on a single remote port.

ZM-9002 Remote

Now the programming technique will not change for this multiple remote trick. You would program the remote control the way you always would. The screenshots are shown below.

First click on Setting to get the drop down menu.

Then click on Remote Setting Wizard

You will then get a display for the remote settings.

Select ZM-9001 for Remote Volume 1

You will then get the options you can set for the remote. Displayed are the popular settings.

If Page is selected as shown for the ZM-IN2 button below, you will get a drop down menu to select

the contact closure input to use on the back panel of the mixer’s chassis and as a trigger for the Page

Event programming.

As you can see, any of the scenes can be chosen, and any input or output can be selected to

be controlled when Volume is selected as a function. Additionally, the resolution of the volume change can be set as well.

So what’s left? Just wire as many ZM-9001 remotes to the remote port that has been programmed in standard parallel fashion. Just be sure to connect them all the same way. DO NOT mix the “E” and “Out” connections. You can also daisy chain one remote to the next, if home run wiring is not being done. That’s it!

Now you may have noticed you have a Remote Volume 2 shown above. This is for your 2nd

2-wire remote port. You can do the same thing with this remote option as well. Double bang for the buck! This option, if your project can make use of it, will save you a few hundred dollars minimum over using the serial remotes. Now the 2-wire remotes and serial remotes each have their own advantages, but this is a simple cost saving control option where applicable.

Some last thoughts.

This could give you volume up and down for 6 inputs, 6 outputs, or combination of 6 input and output channels in a standard 2-gang electrical box with multiple instances. You also could use our trick on one port and use a ZM-9002 on the second port. With this combination, you could as an example, program the ZM-9001 port for volume change for 3 input channels and program the ZM-9002 port so the rotary volume control is used as an output volume control and then program the four buttons for scene change. This would be a great solution when using an A-9060SM2, A-9120SM2 or A-9240SHM2 where the requirements of the project match the maximum number of channels, pages and volume settings to be controlled by ZM-9001 and ZM-9002 remotes. An example of this might be a restaurant where the single ZM-9002 would be located at the bar for scene and output volume control and multiple instance input volume controls would be located around the eating area for up to three sources.

Happy installing!

Thursday, February 6, 2014

9000M2 Software Part 11 - Paging Settings

In this tutorial you

will learn how to adjust Paging settings with the TOA 9000m2 GUI Software

application.

Click the PAGING Button to open the PAGING Setting View. Here you will find priority input sources, trigger functions and output assignments. All settings are stored independent of scene memory.

Here You can program up

to 32 Paging presets.

To program a Paging

Preset, first select the priority input Source.

Then, Select the Trigger

that will activate the paging preset--this may be a contact closure, a button

press from a remote controller keypad, or Vox threshold.

Then, indicate which

outputs the page will be assigned.

Also, a page can be used

to synchronize a contact output relay, this may be useful to trigger

an external piece of equipment. You may sync up to 12 contact outputs when

using the C-001 Expansion Card.

Finally, you can assign

the priority mode to indicate what happens when multiple sources with the same

priority are fed through an output at the same time: Last in First out, First

in First out, or all sources mixed at the same time.

Wednesday, January 8, 2014

Tech Tip: D-901 EQ Settings for TOA Speakers Made Easy

By Jim McGuinness, Product Support Specialist

As we all have heard before time is money, and no one understands that better than the custom integrator or installer. For many jobs, much time and effort goes into the design and deployment of a new sound system. Since many electronic products are programmable these days, time spent on setting up a unit, or group of units to finish a system, is always a concern. Realistically hours can be spent which can burn up your profit ratio on a job. Even if the setup goes perfectly, time just tweaking a new system is costly. Ultimately, you’re trying to hit that sweat spot of profitable job and happy client for future business.

So in comes the question of how can we save time when installing TOA speakers in conjunction with the D-901 mixer. Well we’ve just made it a little easier by taking advantage of some of the flexibility of the D-901’s multi-iteration capable software. We now have several files which contain the EQ curves for many of our popular speakers which can be used like a template. These files can be found at the following link. Having these two files independently opened along with your project file allow you to copy paste the filters from the template EQ files to your project file for the output filters needed.

The first thing you will need to do is download the template zip file from our website to your

Windows compatible computer. You will then need to unzip the file to obtain the two .d9t files which can be saved to your 'My Documents' folder or any folder you decide to place them in.

The second step you should do is to open your project file and have it ready on your computer. The screenshot below is a general example to go to a file location and open a file.

The next step is to open two more iterations of the D-901 software on your PC. Then for each iteration, use the 'Open File' icon again on your tool bar to locate your .d9t template files and open one file in each of your two additional iterations of the software.

TIP: If the type or types of TOA speakers that need to be used all reside on one of these template files, then only the template file of interest needs to be open.

Below you will find the screenshots of these steps. Note that once you open the template files with the software, the speaker names will appear as preset memory names.

Open file example.

Speaker EQs shown as presets once the file is loaded.

To select a particular EQ curve, let’s say the HX-5 in this example, click on the HX-5 Output Filter preset and click on 'Change'.

Then click on the output filter button for any of the output channels to reveal the stored EQ curve.

The output EQ curve will be displayed as shown.

Now that you have the EQ curve of interest loaded, right hand click the same output filter button to reveal additional options and select 'Copy'.

The last step will be to switch over to your project D-901 software, click on the output filter button for the channel that has the HX-5 speaker on it and select 'Paste'. If you have more than one channel with the HX-5 speaker on it, you will need to past the EQ settings for each channel separately.

You will be able to verify the EQ curve in the graphical display at the bottom portion of the software each time you paste an EQ curve into your project.

Lastly when you go to close the template files it will ask you if you want to save the changes as the software has detected a functional change. Say NO to Save file for your Template files and YES to your project file as you don’t want to lose your work.

That’s it, simple and easy, especially if you have several models of speakers you are working with.

Happy programming!

As we all have heard before time is money, and no one understands that better than the custom integrator or installer. For many jobs, much time and effort goes into the design and deployment of a new sound system. Since many electronic products are programmable these days, time spent on setting up a unit, or group of units to finish a system, is always a concern. Realistically hours can be spent which can burn up your profit ratio on a job. Even if the setup goes perfectly, time just tweaking a new system is costly. Ultimately, you’re trying to hit that sweat spot of profitable job and happy client for future business.

So in comes the question of how can we save time when installing TOA speakers in conjunction with the D-901 mixer. Well we’ve just made it a little easier by taking advantage of some of the flexibility of the D-901’s multi-iteration capable software. We now have several files which contain the EQ curves for many of our popular speakers which can be used like a template. These files can be found at the following link. Having these two files independently opened along with your project file allow you to copy paste the filters from the template EQ files to your project file for the output filters needed.

The first thing you will need to do is download the template zip file from our website to your

Windows compatible computer. You will then need to unzip the file to obtain the two .d9t files which can be saved to your 'My Documents' folder or any folder you decide to place them in.

The second step you should do is to open your project file and have it ready on your computer. The screenshot below is a general example to go to a file location and open a file.

The next step is to open two more iterations of the D-901 software on your PC. Then for each iteration, use the 'Open File' icon again on your tool bar to locate your .d9t template files and open one file in each of your two additional iterations of the software.

TIP: If the type or types of TOA speakers that need to be used all reside on one of these template files, then only the template file of interest needs to be open.

Below you will find the screenshots of these steps. Note that once you open the template files with the software, the speaker names will appear as preset memory names.

Open file example.

Speaker EQs shown as presets once the file is loaded.

To select a particular EQ curve, let’s say the HX-5 in this example, click on the HX-5 Output Filter preset and click on 'Change'.

Then click on the output filter button for any of the output channels to reveal the stored EQ curve.

The output EQ curve will be displayed as shown.

Now that you have the EQ curve of interest loaded, right hand click the same output filter button to reveal additional options and select 'Copy'.

The last step will be to switch over to your project D-901 software, click on the output filter button for the channel that has the HX-5 speaker on it and select 'Paste'. If you have more than one channel with the HX-5 speaker on it, you will need to past the EQ settings for each channel separately.

You will be able to verify the EQ curve in the graphical display at the bottom portion of the software each time you paste an EQ curve into your project.

Lastly when you go to close the template files it will ask you if you want to save the changes as the software has detected a functional change. Say NO to Save file for your Template files and YES to your project file as you don’t want to lose your work.

That’s it, simple and easy, especially if you have several models of speakers you are working with.

Happy programming!

Subscribe to:

Comments (Atom)